လျှပ်စစ်ဓာတ်အား အခြေခံအဆောက်အအုံများအတွက် အရေးပါသော ကေဘယ်လ်ထရီ Roll Forming Machines

Cable Tray Roll Forming Machines ကို နားလည်ခြင်း

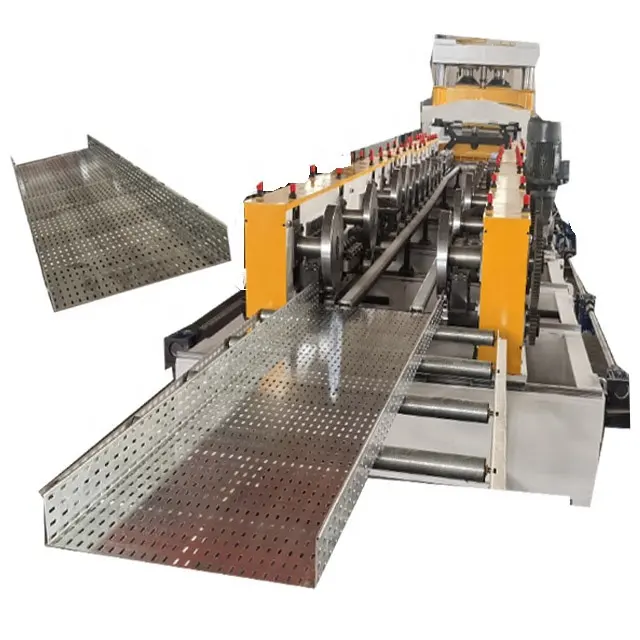

ကေဘယ်လ်ထရီ Roll ပုံသွင်းစက်သည် ကေဘယ်လ်ထရီများကို ပလပ်စတစ်ပြားများမှ ပုံသွင်းထုတ်လုပ်ရန်အတွက် အထူးပြုပစ္စည်းတစ်ခုဖြစ်သည်။ ဒီစက်ဟာ လျှပ်စစ်မီးကြိုးစနစ်တွေရဲ့ အခြေခံအဆောက်အအုံမှာ မရှိမဖြစ် ပါဝင်တဲ့ ကေဘယ်လ်ထရီတွေ ထုတ်လုပ်ရာမှာ အရေးပါတဲ့ အခန်းကဏ္ဍကို သရုပ်ဆောင်ပါတယ်။ ကြိုးပမ်းမှုအတွက် ကြိုးပမ်းမှုအတွက် လိုအပ်တဲ့ အစိတ်အပိုင်းတွေကို အတိအကျ ဖော်ပြပေးရန် လိုအပ်ပါတယ်။ ကုန်သွယ်ရေးနှင့် စက်မှုအဆောက်အအုံများတွင်၊ ဤထုပ်များသည် ပွင့်လင်းသော ကြိုးပမ်းရေးစနစ်များအတွက် ပိုကောင်းမွန်သော အစားထိုးမှုတစ်ခုအဖြစ် ဆောင်ရွက်လျက် အိုင်ဆိုလိတ် ကေဘယ်လ်များကို ထောက်ပံ့ရန် ပိုမိုစီစဉ်ထားပြီး ပြုပြင်ပြောင်းလဲနိုင်သော ချဉ်းကပ်မှုတစ်ခု ပေးသည်။

စက်သည် သံမဏိကြိုးကို အဆက်မပြတ် ရိုလာများဖြင့် ဖြတ်သန်းခြင်းဖြင့် လုပ်ဆောင်ပြီး ၎င်းကို လိုချင်သော ပုံစံသို့ တိုးတက်စွာ ပုံသွင်းပေးသည်။ သံမဏိကြိုးဟာ ရိုလာတွေထဲ ဖြတ်သွားတဲ့အခါ လိုအပ်တဲ့ သတ်မှတ်ချက်တွေအလိုက် ခိုင်မာတဲ့ (သို့) လေသွင်းထားတဲ့ ကေဘယ်လ်တဲအဖြစ် ပြောင်းလဲပါတယ်။ ရိုလ်ပုံစံထုတ်လုပ်မှုလုပ်ငန်းစဉ်သည် တိကျမှုနှင့် ထိရောက်မှုကို အာမခံပေးပြီး ၎င်းသည် ကေဘယ်လ်ထရီများ အစုလိုက်ထုတ်လုပ်ရန်အတွက် အကောင်းဆုံး ဖြေရှင်းနည်းတစ်ခုဖြစ်သည် ဒီထုပ်တွေဟာ လျှပ်စစ်ကြိုးတွေကို နေရာအမျိုးမျိုးမှာ ခိုင်မာတဲ့ အထောက်အပံ့ပေးပြီး တပ်ဆင်မှုကို လွယ်ကူစေပြီး ကြိုးစနစ်တွေကို မွမ်းမံတဲ့အခါ လွယ်ကူတဲ့ ပြုပြင်ပြောင်းလဲမှုတွေ လုပ်ခွင့်ပေးပါတယ်။

Cable Tray Roll Forming Machines ၏ အဓိက အစိတ်အပိုင်းများ

Cable tray roll forming machine တွေဟာ နောက်ဆုံးထုတ်ကုန်ရဲ့ တိကျမှုနဲ့ အရည်အသွေးကို အာမခံပေးတဲ့ အဓိက အစိတ်အပိုင်းများစွာနဲ့ ပြုလုပ်ထားတာပါ။ ဒီအပိုင်းတွေထဲမှာ ပုံမှန်အားဖြင့် အောက်ပါတွေ ပါဝင်ပါတယ်။

- အိတ်ဖွင့်စက် : ဒီအပိုင်းက သံချပ်ပြားတွေကို စက်ထဲကို ထည့်ပေးပြီး သံမဏိကို ချည်ပေးတယ်။

- လှိမ့်စက် : ဒါကတော့ ရိုလာပုံစံထုတ်တဲ့ လုပ်ငန်းစဉ်ရဲ့ ဗဟိုချက် ဖြစ်ပျက်ရာ၊ သံမဏိကို ရိုလာတစ်သီကြီးနဲ့ ပုံသွင်းတာပါ။

- ဖြတ်စက် : ၎င်းသည် ပုံသွင်းထားသော သတ္တုကို သတ်မှတ်ထားသော အလျားများသို့ ဖြတ်တောက်ကာ အပိုင်းတိုင်းတွင် တည်ငြိမ်မှုကို အာမခံပေးသည်။

- ရေအားစနစ် : ဖြတ်တောက်ခြင်းနှင့် ပုံသွင်းခြင်းလုပ်ငန်းစဉ်များအတွက် လိုအပ်သော အားကို ပေးသည်။

အစိတ်အပိုင်းတစ်ခုစီဟာ ကေဘယ်လ်ထည့်သွင်းတဲ့ ထုတ်လုပ်မှု လုပ်ငန်းစဉ်ရဲ့ တိကျမှုနဲ့ ထိရောက်မှုကို ထောက်ပံ့တဲ့ မပြတ်သားတဲ့ ကဏ္ဍတစ်ခု ပါဝင်ပါတယ်။

ခေတ်သစ် ကြိုးထုပ်အလှည့် ပုံသွင်းစက်များတွင် အဆင့်မြင့် အလိုအလျောက်စနစ်များနှင့် ထိန်းချုပ်ရေးစနစ်များ ပါဝင်သည်။ ဒီနည်းပညာ တိုးတက်မှုတွေဟာ လူသားအမှားတွေကို လျှော့ချခြင်းအားဖြင့် တိကျမှုကို မြှင့်တင်ပေးတယ်၊ စက်ပစ္စည်းတွေသုံးပြီး အလုပ်သမား ကုန်ကျစရိတ်ကို လျှော့ချပေးပြီး ထုတ်လုပ်မှု လုပ်ငန်းစဉ်ကို ချောမွေ့စေခြင်းအားဖြင့် လုပ်ငန်းရဲ့ စုစုပေါင်း ထိရောက်မှုကို မြှင့်တင်ပေးတယ်။ အလိုအလျောက်စနစ်များတွင် မကြာခဏဆိုသလို ပရိုဂရမ်လုပ်လို့ရတဲ့ logic controller (PLC) များနှင့် real-time monitoring နှင့် adjustment များကို ပြုလုပ်ပေးသော sensor များကဲ့သို့သော features များပါဝင်ပြီး ထုတ်လုပ်မှုလိုင်းကို ပိုမိုကောင်းမွန်သော စွမ်းဆောင်ရည်နှင့် ယုံကြည်မှုရှိမှုအတွက် အကောင်းဆုံးပြုပြင်ပေးသည်။

Cable Tray Roll Forming Machines ၏ အကျိုးကျေးဇူးများ

Cable tray roll forming machines သည် အမှိုက်များကို အနည်းဆုံးထိ လျှော့ချပြီး သတ္တုပြားလုပ်ငန်းစဉ်အတွင်း ကုန်ကြမ်းများကို အကောင်းဆုံး အသုံးပြုခြင်းဖြင့် သိသာသော ကုန်ကျစရိတ်ထိရောက်မှုကို ပေးသည်။ ဒီစက်တွေက အရွယ်အစားနဲ့ အပိုင်းတွေကို အလိုအလျောက် ညှိပေးလျက် အနည်းဆုံး ကုန်ကြမ်းဖြုန်းတီးမှုရှိရင်း တိကျတဲ့ တိုင်းတာမှုတွေ လုပ်ပေးပါတယ်။ အဲဒါဟာ ကုန်ကြမ်း ကုန်ကျစရိတ်ကို သိသိသာသာ ချွေတာပေးလျက် ထုတ်လုပ်ရေး လုပ်ငန်းရဲ့ စုစုပေါင်း ဘတ်ဂျက်ကို အပြုသဘော သက်ရောက်မှု ရှိစေနိုင်ပါတယ်။

ဒါ့အပြင် ဒီစက်တွေဟာ ထုတ်လုပ်မှုနှုန်းကို မြှင့်တင်ပြီး အရည်အသွေး အဆင့်မြင့်တဲ့ စံနှုန်းတွေကို ထိန်းသိမ်းရာမှာ ထူးခြားပါတယ်။ အချိန်ကုန်ပြီး အမှားများတတ်တဲ့ ဖြတ်တောက်ခြင်းနဲ့ အံဆွဲခြင်းလို အစဉ်အလာနည်းလမ်းတွေနဲ့မတူဘဲ ကြိုးထုပ်ထုပ်ပုံစံထုတ်စက်တွေဟာ ထုတ်လုပ်မှုကို အရှိန်မြှင့်ပေးတဲ့ ဆက်တိုက်ခေါက်ခြင်းလုပ်ငန်းစဉ်ကို အသုံးပြုပါတယ်။ ကွန်ပျူတာနည်းပညာရဲ့ အကူအညီနဲ့ ဒီစက်တွေဟာ အပိုင်းတိုင်းဟာ တစ်မျိုးတည်းဖြစ်တာကို သေချာစေပြီး စက်မှုလုပ်ငန်းရဲ့ အရည်အသွေး သတ်မှတ်ချက်တွေကို အမြဲတမ်း ဖြည့်ဆည်းပေးပါတယ်။ အမြန်နှုန်းနဲ့ တိကျမှု ပေါင်းစပ်မှုက ကြီးမားတဲ့ အမှာစာတွေကို ချက်ချင်း ဖြည့်ဆည်းပေးရုံသာမက ထုတ်ကုန်တွေအကြား တစ်သမတ်တည်းဖြစ်မှုကို အာမခံပေးပြီး ဖောက်သည်တွေကြား ယုံကြည်မှုနဲ့ ကျေနပ်မှုကို မြှင့်တင်ပေးပါတယ်။

ထုတ်လုပ်သော Cable Tray စနစ်အမျိုးအစားများ

ကေဘယ်လ်ထရီစနစ်တွေဟာ အမျိုးမျိုးရှိပြီး တစ်ခုစီဟာ လျှပ်စစ်တပ်ဆင်မှုတွေမှာ သီးခြားလိုအပ်ချက်တွေကို ဖြည့်ဆည်းဖို့ ပုံစံထုတ်ထားတာပါ။ လှေကားလို ကေဘယ်လ်အိုးများ စွမ်းအင်ဖြန့်ဖြူးရေး နေရာတွေမှာ လူကြိုက်များတဲ့ ရွေးချယ်မှုပါ။ [စာမျက်နှာ ၂၇ ပါ ရုပ်ပုံ] ၎င်းသည် ဝန်ကြီးသော ကြိုးများကို လုံခြုံစွာ ထောက်ပံ့ပေးရုံသာမက အပူကို ဖြာထွက်စေရန် ထိရောက်သော လေလည်ပတ်မှုကိုလည်း အားပေးပြီး ကြိုး၏ အကောင်းဆုံး စွမ်းဆောင်ရည်ကို အာမခံပေးသည်။

ပုံးအမျိုးအစား ကြိုးပုံးပုံးများ ၎င်းတို့ရဲ့ ကျယ်ပြန့်တဲ့ အောက်ခြေနဲ့ ဘေးတွေကြောင့် အရွယ်စုံမှုကို ပေးပါတယ်။ ဒီထုပ်တွေမှာ ကြိုးကိုင်မှု ပိုကောင်းစေဖို့နဲ့ ထောက်ပံ့ဖို့ ပစ္စည်းစုံ တပ်ဆင်ထားပါတယ်။ ဒီအမျိုးအစားဟာ ကြိုးတွေကို မကြာခဏ ပြန်လည်လမ်းကြောင်းပြောင်းဖို့ (သို့) ပြန်လည်စီစဉ်ဖို့ လိုအပ်တဲ့ ပတ်ဝန်းကျင်တွေမှာ အထူးအသုံးဝင်ပြီး လွယ်ကူတဲ့ ဝင်ရောက်မှုနဲ့ ပြင်ဆင်မှု ရွေးချယ်မှုတွေကို ပေးပါတယ်။

ဒေတာစင်တာ (သို့) သေးငယ်တဲ့ အဆောက်အအုံလို အသေးစား အဆောက်အအုံတွေအတွက် ကွင်းဆက်လိုင်းအိုးများ အကောင်းဆုံးပါ။ ၎င်းတို့ဟာ ကေဘယ်လ်အရေအတွက်ကို ကန့်သတ်ထားရန် ပုံစံထုတ်ထားပြီး ကန့်သတ်ထားတဲ့ နေရာများတွင် ကောင်းမွန်စွာ တပ်ဆင်နိုင်ကာ ကေဘယ်လ်များကို စနစ်တကျ လမ်းကြောင်းချပေးရန် ခွင့်ပြုပေးပါတယ်။ ၎င်းတို့ရဲ့ သေးငယ်တဲ့ ပုံစံက ကြိုးတွေကို ထိရောက်စွာ ဖြန့်ဝေပေးရင်း အမှိုက်ကင်းတဲ့ ပတ်ဝန်းကျင်ကို ထိန်းသိမ်းဖို့ ကူညီပေးပါတယ်။

ကေဘယ်လ်ထရီ စီမံကိန်းများတွင် လုံခြုံရေးနှင့် လုပ်ဆောင်မှု

ကေဘယ်လ်ထရီ စီမံကိန်းများတွင် ဘေးကင်းလုံခြုံမှုနှင့် လုပ်ဆောင်နိုင်စွမ်းကို အာမခံပေးရန်သည် အရေးကြီးပြီး လုပ်ငန်းစံနှုန်းများအား လိုက်နာခြင်းသည် အဓိက အစိတ်အပိုင်းတစ်ခုဖြစ်သည်။ National Electrical Manufacturers Association (NEMA) က သတ်မှတ်ထားသည့် လုံခြုံရေး စံနှုန်းများနှင့်အညီ ကေဘယ်လ်ထရီ တပ်ဆင်မှု၏ လုံခြုံရေးနှင့် ထိရောက်မှုကို အာမခံပေးသည်။ ဤစံနှုန်းများတွင် ကေဘယ်လ်ထရီစနစ်များ အောင်မြင်စွာ လည်ပတ်နိုင်ရန်အတွက် အရေးပါသော စက်မှုစွမ်းဆောင်ရည်၊ ဝန်ထုပ်နှုန်းများနှင့် အပျက်အစီးခံနိုင်မှု အပါအဝင် ရှုထောင့်အမျိုးမျိုးကို ဖော်ပြထားသည်။

ထိရောက်တဲ့ တပ်ဆင်မှု လုပ်နည်းတွေဟာ ဘေးကင်းလုံခြုံမှုနဲ့ လုပ်ဆောင်မှု ထိန်းသိမ်းရာမှာလည်း အရေးပါတဲ့ ကဏ္ဍတစ်ခု ပါဝင်ပါတယ်။ တပ်ဆင်နေစဉ် အလုပ်သမားတွေကို ကာကွယ်ဖို့ သင့်တော်တဲ့ သင်တန်းနဲ့ လုံခြုံရေး ကိရိယာတွေ အသုံးပြုဖို့ လိုအပ်ပါတယ်။ ထို့အပြင် ထုတ်လုပ်သူ၏ လမ်းညွှန်ချက်များကို လိုက်နာခြင်းသည် ကေဘယ်လ်ထရီစနစ်များ မှန်ကန်စွာနှင့် ထိရောက်စွာ အလုပ်လုပ်နိုင်ရန် အာမခံပေးသည်။ ဒီလုပ်ထုံးလုပ်နည်းတွေကို လိုက်နာခြင်းက အလုပ်သမားတွေကို ကာကွယ်ပေးရုံသာမက ကေဘယ်လ်ထရီစနစ်တွေရဲ့ သက်တမ်းနဲ့ စွမ်းဆောင်ရည်ကိုလည်း တိုးမြှင့်ပေးပါတယ်။ ယေဘုယျအားဖြင့်၊ စံနှုန်းများနှင့် တပ်ဆင်မှု နည်းစနစ်များ နှစ်ခုစလုံးအပေါ် အာရုံစိုက်မှုဟာ ယုံကြည်စိတ်ချရပြီး လုံခြုံတဲ့ ကေဘယ်လ် လမ်းကြောင်း ဖြေရှင်းနည်းများ ရရှိရန်အတွက် အဓိကပါ။

Featured Cable Tray Roll Forming Machines များအတွက် အသုံးပြုမှု

ကေဘယ်လ်ထရီ ဖြေရှင်းနည်းတွေကို သုံးနိုင်စွမ်းရှိတယ်ဆိုရင် Cable Tray Roll Forming Machine/Cable Ladder ထုတ်လုပ်ရေး စက် ၎င်းရဲ့ လိုက်လျောညီထွေမှုနဲ့ စွမ်းဆောင်ရည်မြင့်မားမှုကြောင့် ထင်ရှားပါတယ်။ ဒီမော်ဒယ်ကို ကျင့်သုံးနိုင်စွမ်းအတွက် အထူးပြုပြီး ပုံစံအမျိုးမျိုးဖြင့် ထုတ်လုပ်ထားပြီး လုပ်ငန်းအမျိုးမျိုးရဲ့ လိုအပ်ချက်တွေကို ဖြည့်ဆည်းပေးနိုင်ပါတယ်။ ၎င်း၏ အလိုအလျောက် လုပ်ဆောင်ချက်များသည် အဆက်မပြတ် လုပ်ဆောင်မှုနှင့် တိုးတက်သော ထုတ်လုပ်မှုကို အာမခံပေးပြီး ထုတ်လုပ်သူများအတွက် တန်ဖိုးမဖြတ်နိုင်သော အရင်းအမြစ်တစ်ခု ဖြစ်လာစေသည်။

၎င်း အပြည့်အဝ အလိုအလျောက် ပုံသွင်းစက် စက်ရုပ်စနစ်ဖြင့် ရိုလ် ပုံသွင်းမှု လုပ်ငန်းစဉ်ကို တော်လှန်ပြောင်းလဲပေးပြီး လက်လုပ်အားကို သိသိသာသာ လျော့ကျစေပါတယ်။ ဒီပမာဏမြင့် ထုတ်လုပ်ရေးစက်က အမှားတွေကို အနည်းဆုံးထိ လျှော့ချပေးပြီး ထုတ်လုပ်တဲ့ ကေဘယ်လ်ထရီအားလုံးမှာ တစ်သမတ်တည်း အရည်အသွေးကို အာမခံပေးပါတယ်။ ထုတ်လုပ်မှု ထိရောက်မှုကို အကောင်းဆုံး လုပ်ချင်တဲ့ လုပ်ငန်းတွေအတွက် အကောင်းဆုံး ရွေးချယ်မှုပါ။

ခိုင်မာတဲ့ တည်ဆောက်မှု လိုအပ်တဲ့ ဝန်ထုပ်ဝန်ပိုးများအတွက် သံမဏိ သံမဏိ ကြိုးလှေခါးဘေး ပုံသွင်းစက် မနှိုင်းယှဉ်နိုင်ပါ။ သံနှင့် သံမဏိမှ ရေရှည်ခံနိုင်သော ကြိုးပမ်းရေး ထုပ်များကို ထုတ်လုပ်ရာတွင် အထူးပြုထားသော ဤစက်သည် ယုံကြည်စိတ်ချရပြီး ရေရှည်ခံနိုင်သော ထုပ် တည်ဆောက်မှု လိုအပ်သည့် စက်မှုလုပ်ငန်းများအတွက် မရှိမဖြစ်လိုအပ်ပါသည်။

နောက်ဆုံးတွင်၊ ရောင်းအားပြင်းထန်သော Full Automatic 100-600mm Cable Tray Roll Forming Machine ကို အမြန်ဆုံး တပ်ဆင်ပြီး လည်ပတ်နိုင်ဖို့ အဆင့်မြင့် နည်းပညာတွေနဲ့ တပ်ဆင်ထားပါတယ်။ ထုတ်လုပ်သူတွေဟာ ထုတ်လုပ်မှုကို မြှင့်တင်ဖို့နဲ့ မြန်မြန်ဆန်ဆန် ပြင်ဆင်နိုင်စွမ်းကြောင့် တပ်ဆင်ချိန်ကို လျှော့ချဖို့ အကောင်းဆုံးပါ။

ဒီစက်တွေဟာ စက်မှုသုံးပစ္စည်း အမျိုးမျိုးအတွက် အသင့်ပြင်ထားတဲ့ ကြိုးအိုးစနစ်တွေကို ထုတ်လုပ်ဖို့ လိုအပ်တဲ့ အရည်အသွေးမြင့် ကိရိယာတွေရဲ့ အပိုင်းတစ်ပိုင်းပါ။

ကောက်ချက်: Cable Tray Roll Forming Machines ၏ အနာဂတ်

စမတ်ထုတ်လုပ်မှုနှင့် IoT ပေါင်းစည်းခြင်းကဲ့သို့သော နည်းပညာပေါ်ပေါက်လာသော အလားအလာများသည် ကေဘယ်လ်ထရီထုတ်လုပ်မှု အနာဂတ်ကို သိသိသာသာ ပုံသွင်းနေသည်။ ဒီတိုးတက်မှုတွေက အချိန်နဲ့တပြေးညီ စောင့်ကြည့်မှုနဲ့ ထိန်းချုပ်မှုကို ဖြစ်ပေါ်စေပြီး ထိရောက်မှုကို မြှင့်တင်ပြီး အမှားတွေကို လျှော့ချပေးပါတယ်။ ဒီတီထွင်ဆန်းသစ်မှုတွေကို လက်ခံခြင်းအားဖြင့် ထုတ်လုပ်သူတွေဟာ ထုတ်လုပ်မှု တိုးတက်စေပြီး ထုတ်ကုန် အရည်အသွေးကို အာမခံနိုင်ကာ ပိုရှုပ်ထွေးပြီး တုံ့ပြန်မှုရှိတဲ့ ထုတ်လုပ်မှု ပတ်ဝန်းကျင်အတွက် လမ်းဖွင့်ပေးနိုင်ပါတယ်။

မှန်ကန်သော စကေးပုံစံထုတ်စက်ကို ရွေးချယ်ခြင်းသည် အရေးကြီးပြီး ထုတ်လုပ်မှုပမာဏ၊ ပစ္စည်းများနှင့် စီမံကိန်းဆိုင်ရာ သီးခြားလိုအပ်ချက်များကဲ့သို့သော အကြောင်းရင်းများဖြင့် လမ်းညွှန်သင့်သည်။ ထုတ်လုပ်သူတွေဟာ သူတို့ရဲ့ လုပ်ငန်းရည်မှန်းချက်တွေနဲ့ ကိုက်ညီတဲ့ ပစ္စည်းကိရိယာတွေကို ရွေးချယ်ဖို့ လိုအပ်ချက်တွေကို ဂရုတစိုက် အကဲဖြတ်ဖို့လိုပါတယ်။ ဒါက ထိရောက်မှုတင်မကပဲ ကုန်ကျစရိတ်ထိရောက်မှုနဲ့ အနာဂတ် လိုအပ်ချက်တွေကို လိုက်ဖက်အောင် လုပ်နိုင်စွမ်းကိုပါ အာမခံပေးပါတယ်။

EN

EN