The Role of Perforated roof Panel Forming in Modern Construction

Advantages of Perforated Roof Panels in Modern Construction

Enhanced Ventilation and Airflow Control

Perforated roof panels are a game-changer in modern construction, greatly enhancing ventilation and airflow management for buildings. By facilitating better airflow, these panels help maintain efficient ventilation systems across both residential and commercial structures. This ventilation efficiency is essential as it significantly reduces humidity and heat buildup, thereby enhancing indoor air quality. According to studies on energy efficiency, buildings with improved ventilation can potentially reduce their energy consumption by 20%. This kind of advantage underscores the importance of integrating perforated panels in contemporary architecture designs for optimal indoor climate control.

Energy Efficiency Through Solar Shading

One of the standout advantages of perforated roof panels is their contribution to energy efficiency through effective solar shading. These panels act as a barrier to direct sunlight, reducing reliance on air conditioning systems and thereby enhancing energy conservation. According to the Department of Energy, utilizing shading solutions such as perforated panels can lower energy consumption by up to 30%. Incorporating these panels aligns with sustainable practices, making buildings eligible for LEED credits—a prestigious marker for green construction. Thus, perforated panels not only enhance aesthetic appeal but also drive forward-thinking energy solutions in modern architecture.

Aesthetic Versatility for Contemporary Designs

The aesthetic versatility of perforated roof panels allows architects and builders to create visually stunning structures that stand out in contemporary design. These panels can be tailor-made in various patterns and finishes, ensuring they complement the stylistic needs of modern architectural phenomenons. Architectural experts emphasize that aesthetics play a crucial role in enhancing property value and marketability. By incorporating perforated panels, structures achieve a distinctive and innovative appearance which can also elevate their appeal in competitive property markets, marking them as an indispensable element in contemporary construction practices.

Key Applications of Perforated Panel Forming

Ventilated Soffits and Roof Decking Systems

Ventilated soffits and roof decking systems leverage perforated roof panels to significantly enhance airflow within roof spaces, effectively preventing moisture buildup. By promoting proper ventilation, these systems contribute to extending the lifespan of roofing materials, ensuring a more durable and maintenance-free structure. Research shows effective soffit ventilation can reduce the incidence of roofing material failure by up to 25%. This not only preserves the structural integrity but also enhances energy efficiency and mitigates maintenance costs, making ventilated systems a staple in both residential and commercial buildings.

Acoustic Management in Large Spaces

Perforated panels are indispensable in managing acoustics in large commercial spaces, such as auditoriums and malls. They effectively absorb sound, reducing noise levels and enhancing the auditory experience within these environments. Studies indicate that incorporating perforated materials can lower sound reverberation by up to 40% in such spaces, creating a more conducive atmosphere for occupants. This not only improves speech intelligibility but also increases comfort for those inside. Investing in acoustic management through perforated panels is crucial for environments where clarity and sound quality are particularly important.

Architectural Facades for Commercial Buildings

In contemporary architecture, perforated panels are increasingly utilized in commercial building facades for both aesthetic and practical advantages. These panels allow for creative designs that enhance visual appeal while also optimizing natural light penetration and reducing thermal gain. Studies have demonstrated that perforated facades can significantly improve a building's energy efficiency ratings. Additionally, they offer a unique solution for architects aiming to balance aesthetics with functionality, therefore playing a pivotal role in sustainable architectural practices. The dual benefits make perforated facades an appealing choice for modern commercial constructions.

The Roll Forming Process Behind Perforated Panels

Precision Punching vs. Lancing Techniques

When creating perforated panels, two primary techniques are employed: precision punching and lancing. Precision punching is renowned for its accuracy and reproducibility, making it ideal for intricate designs, especially in aesthetic applications. This technique is highly regarded for its ability to maintain the integrity of complex patterns without compromising quality. On the other hand, lancing involves stretching a portion of the metal to create openings, often resulting in varied finishes. For most commercial projects, precision punching is the recommended standard due to its cost-effectiveness and efficiency, ensuring panels meet desired specifications without excessive expenditure.

Integration with Roll Forming Machines

Roll forming machines play a critical role in the production of durable perforated panels by seamlessly integrating with the perforation process. These machines automate the roll forming operations, significantly boosting production efficiency and reducing the reliance on manual labor. This integration is especially crucial in the context of modern construction demands, where timely panel production is necessary. Research indicates that using roll forming machinery in conjunction with perforation techniques can diminish production times by up to 30%, making it an essential technology for achieving rapid and reliable manufacturing outcomes. By harmonizing roll forming and perforation, businesses can deliver high-quality panels tailored to specific project needs.

Innovative Machinery for Perforated Panel Production

5T Hydraulic Decoiler for Precision Uncoiling

The 5T Hydraulic Decoiler plays a pivotal role in the initial stages of perforated panel production, ensuring precision uncoiling. This advanced machine maintains consistent tension, which is crucial for achieving the desired quality in the final product. With consistent performance, it reduces the likelihood of material defects, thereby ensuring that the panels meet high-quality standards. Studies highlight that employing such advanced decoilers can boost work efficiency by as much as 20%, making it a worthwhile investment for manufacturers focusing on precision and efficiency.

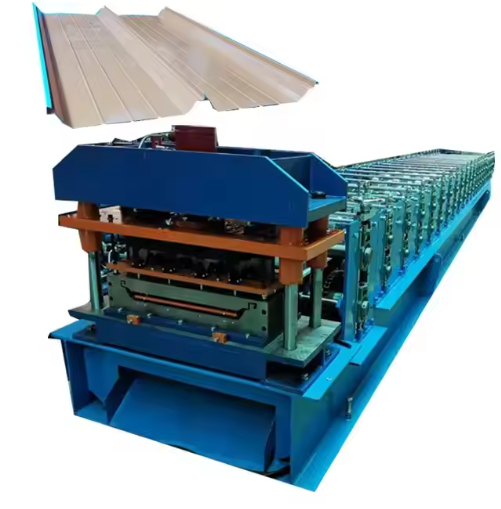

Railway Carriage Board Roll Forming Machine

Specialized roll forming machines, such as the Railway Carriage Board Roll Forming Machine, are crucial in the production of heavy-duty materials tailored for railway applications. These machines are known for their robustness and precision, making them ideal for crafting components that withstand the rigors of railway operations. Their efficiency extends to improving the structural integrity of materials, significantly enhancing the safety and reliability of railway constructions. Industry experts assert that the utilization of such machines boosts production capacity while concurrently minimizing labor demands, resulting in improved overall efficiency for manufacturers.

Tile Corrugated Steel Roof Roll Former

The Tile Corrugated Steel Roof Roll Former is designed to efficiently produce corrugated roofing panels, which are highly sought after in modern construction. This machine minimizes material waste through precision forming techniques, thus enhancing both cost-effectiveness and structural integrity of the panels. By significantly reducing wastage, it helps manufacturers to cut down expenses related to material procurement, contributing to an average 15% cost saving in materials, according to industry reports. The streamlined production process of this machine also ensures high-speed output without compromising on quality.

Vertical Roof Panel Roll Forming System

Vertical roll forming systems, such as the Vertical Roof Panel Roll Forming System, have revolutionized the way panels are crafted by streamlining manufacturing workflows. These systems enhance the precision and durability of the panels they produce, resulting in superior product quality that boosts building integrity. A notable advantage is their ability to create panels with exact profiles, which is pivotal for achieving modern architectural excellence. As reported in trade publications, companies that implement vertical systems may see a reduction in production lead times by up to 25%, highlighting their efficiency in meeting project deadlines.

Future Trends in Perforated Roof Technology

Smart Panels with Integrated IoT Sensors

Smart panels integrating IoT sensors are shaping the future of building technology by enhancing interactivity and enabling advanced diagnostics for maintenance purposes. These innovative technologies offer real-time data on energy usage and environmental conditions, which facilitate proactive management of building systems. As these intelligent solutions advance, forecasts show that the smart building market is poised to expand by 30% over the next five years. This growth is driven by the increasing adoption of smart panels and similar technologies that align with modern sustainability goals.

Sustainable Material Innovations

The demand for sustainable materials in construction is growing, leading to innovations like eco-friendly perforated panels made from recycled content. This shift is not only crucial for reducing buildings' carbon footprints but also aligns with global environmental goals. A report by sustainable building councils emphasizes that employing such innovative materials can enhance energy efficiency by about 20%, underscoring their vital role in achieving sustainability in architecture. By adopting these materials, the construction industry can significantly contribute to a greener future.

EN

EN